FEAKU Series Hydraulic Solenoid valve Coil Mfz8-60y

Hlinzeka ngekhono

Ukuthengisa amayunithi: into eyodwa

Ubukhulu bephakheji elilodwa: 7x4x5 cm

Isisindo esisodwa esiphelele: 0.300 kg

Isingeniso Somkhiqizo

I-1, i-solenoid valve factory solenoid valve coil umjikelezo omfushane noma umjikelezo ovulekile:

Indlela yokutholwa: Okokuqala, ukukala ukuvala i-multimeter, futhi inani lokumelana lisondela ku-zero noma i-infinity, elibonisa ukuthi ikhoyili lizungeza noma livulekele. Uma ukumelana okulinganiselwe kuvamile (cishe amashumi ambalwa ama-ohms), akunakushiwo ukuthi ikhoyili kufanele kube kuhle (ngake ngalinganisa ukumelana kwe-solenoid valve ezungeze i-coil ye-solenoud valve edlula ngenhlamvu ye-solenoid valve edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil edlula nge-solenoid valve coil, bese unika amandla i-solenoid I-Valve. Uma kuzwakala kazibuthe, khona-ke ikhoyili ye-solenoid valve yinhle, ngaphandle kwalokho kubi.

Isixazululo: Faka esikhundleni sekhoyili ye-solenoid valve.

2. Kukhona okungahambi kahle nge-plug / isokhethi:

I-Fault Phenomenon ye-solenoid valve efektri ye-solenoid valve:

Uma i-solenoid valve ine-plug / isokhethi, kungahle kube nezinkinga ngomhlanga wensimbi (engihlangabezana nazo)), izinkinga ze-wiring engizihlangane nazo) Kungcono ukwakha umkhuba: skroma isikulufa sokulungisa ngemuva kokuthi ipulaki lifakwe kwisokhethi, bese liklebhula i-nati yokulungisa ku-coil ngemuva kwenduku ye-spool ngemuva kwenduku ye-spool.

Uma ipulaki yekhoyili ye-solenoid valve ifakwe inkomba yamandla e-LED, kufanele ixhunywe lapho amandla we-DC esetshenziselwa ukushayela i-solenoid valve, ngaphandle kwalokho inkomba ngeke ikhanyise. Ngaphezu kwalokho, ungaguquli ama-plugs anamandla okukhonjiswa kwamandla we-LED kwamazinga ahlukene ama-voltage, azokwenza ukuthi i-LED ishiswe ngaphandle / i-LED enezinga eliphansi noma i-LED ukuze ishiye ukukhanya okuphezulu kakhulu).

Uma kungekho ukukhanya kwenkomba yamandla, i-solenoid valve coil ayidingi ukuba yi-poliaritor (ngokungafani nesikhathi sokuvutha se-transistor kanye nokudluliselwa kwe-DC Coil okuxhumene nokufana kwe-DC's

Indlela yokwelashwa ye-solenoid valve ye-solenoid valve valve ye-solenoid: iphutha elifanele le-wiring, ukulungisa noma ukufaka esikhundleni se-plug nesokhethi.

I-3. I-Valve Core Inkinga:

I-Fault Phenomenon 1: Lapho ingcindezi ye-Liquand nge-Solenoid Valve ijwayelekile, i-solenoid valve ayiphenduli lapho inkinobho ebomvu ye-solenoid valve icindezelwe (i-medium medium ayiguquki), okukhombisa ukuthi umnyombo we-valve kumele abe mubi.

Indlela yokwelashwa: Bheka ukuthi ngabe kukhona yini inkinga nge-medium, okufana nokuthi ngabe kukhona okuningi okuqongelelwe umoya ngomoya ocindezelwe, ikakhulukazi lapho kukhona amapayipi amaningi aqongelelekile, noma ngabe kunamanzi amaningi aqoqiwe, noma ngabe kunokungcola okuningi okuphakathi nendawo. Bese ususa amanzi aqoqiwe noma ukungcola ku-solenoid valve nepayipi. Uma kungasebenzi, sicela uyilungise (uma unesikhathi, ukubekezela futhi uyidinga noma ungene esikhundleni se-valve core, noma umane ungene esikhundleni se-solenoid valve yonke.

I-Fault Phenomenon 2: Ngemuva kokuhlolwa, ikhoyili yikhoyili yoqobo kanye nobude bekholi bujwayelekile lapho bunamandla, kepha i-solenoid valve abasenzi isenzo (okwamanje, umsebenzi we-solenoid we-valve ye-solenoid ungaba yinto ejwayelekile), okukhombisa ukuthi umnyombo we-valve mubi.

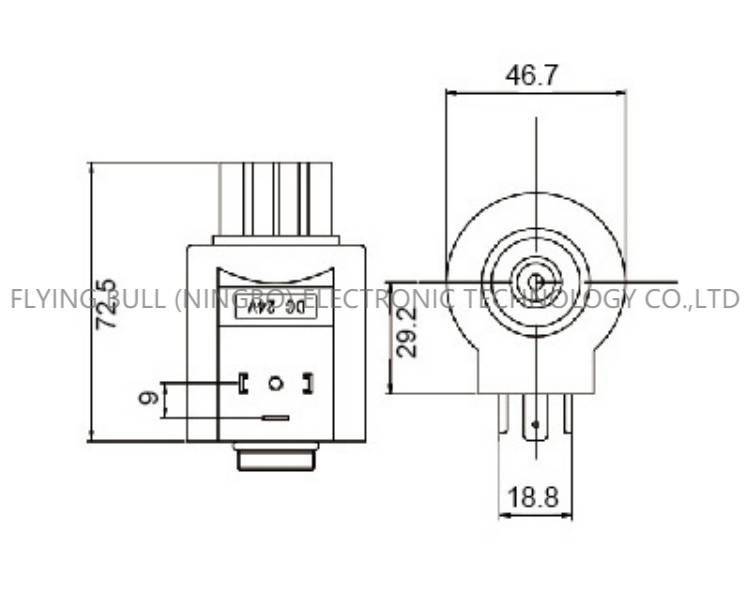

Isithombe somkhiqizo

Imininingwane yenkampani

Inzuzo Yenkampani

Ukuthutha

Umthandi