Ukufakwa kwe-pneumatic kudlala indima ebaluleke kakhulu ezimbonini ngokuxhuma nokwenza kahle izinhlelo ze-pneumatic. Ukubaluleka kwazo kwemikhakha emikhakheni efana nokukhiqiza, ukunakekelwa kwempilo kanye ne-aerospace. Ukukhula kwemakethe kukhombisa ezengeziwe ezenzakalelayo kanye nemiklamo esebenza kahle. Izinto ezintsha, njengeI-Meterproof Isixhumi se-Monobile Screen Socket Socket H034-2, kukhombisa ukuveza ukuthi izixazululo ezisethuthukile zihlangabezana nezidingo zezimboni.

Ukuthathwa Key

- Sebenzisa i-IOT ezinhlelweni ze-pneumatic zokuqapha kanye nokulungiswa bukhoma. Lokhu kubambezeleka okuphansi futhi kuqinisa ukusebenza kahle komsebenzi.

- Khetha izinketho ze-pneumatic eziluhlaza ukonga amandla futhi usize iplanethi. Imiklamo engcono inganciphisa izikweletu zamandla ngo-20%.

- Khetha izingxenye ezincane ze-pneumatic ukuze ugcine isikhala futhi usebenze kangcono. Lezi zingxenye zithuthukisa ukunemba futhi zilungele amarobhothi nokunakekelwa kwempilo.

Izinhlelo ze-smart pneumatic kanye ukuhlanganiswa kwe-iot

Izinhlelo ezixhunyiwe ze-pneumatic

Ukunyuka kwezinhlelo ze-pneumatic ezixhunyiwe kuguqule imisebenzi yezimboni. Ngokuhlanganisa ukuxhumana okungenantambo kanye nezinqubomgomo zokuxhumana ezithuthukile, lezi zinhlelo zinika amandla ukushintshaniswa kwedatha okungenamthungo phakathi kwezakhi. Isibonelo, uchungechunge lwe-AMS oluvela ku-SMC lukhombisa ukuthi ubuchwepheshe obungenawaya buthuthukisa ukuguquguquka kanjani ngokufakwa futhi kuthuthukise ukusebenza kohlelo lonke. Ukuxhumana futhi kuvumela ukuhlaziya okusezingeni ledivayisi, ukuhlinzeka ngokuxilongwa kwangempela kanye namasheke ezempilo. Lokhu kunamandla kuqinisekisa ukuthi izingqinamba ezingaba khona zibhekiswe ngaphambi kokuba zikhuphuke, zikhulisa kakhulu umkhiqizo nokusebenza kahle.

Ukuqapha real-time kanye nokulondolozwa kokubikezela

Ukuqapha kwesikhathi sangempela sekuyitshe le-CENNERRECE LAMABHODI WEZIMALI. Ngokufaka izinzwa ezinikwe amandla ama-Iot, lezi zinhlelo ngokuqhubekayo zilandelela amamethrikhi wokusebenza, njengengcindezelo namanani wokugeleza. Le datha isekela ukulungiswa kokubikezela, okuvimbela isikhathi sokuphumula esingahleliwe ngokukhomba izindaba ezinjengezihlungi ezivalekile kusenesikhathi. Ngokusho kokuqonda kwemboni, ukunakekelwa kokubikezela kunciphisa izindleko zokulungiswa, kuthuthukisa ikhwalithi yomkhiqizo, futhi kunciphise amanani e-scrap. Isibonelo, izexwayiso zokuqala zokwehluleka kwemishini zithuthukisa ukusebenza kwezinto zokukhiqiza futhi zinciphise imfucuza, ukwenza imisebenzi eqhubekayo futhi kungabizi kakhulu.

| Zuza | Ukufanisa |

|---|---|

| Ukuncishiswa kwezindleko | Kuvimbela ukulimala okulandelayo kusuka ekuqhekekeni, ukunciphisa izindleko zokulungisa. |

| Ikhwalithi Yomkhiqizo Ethuthukisiwe | Ikhipha imikhiqizo enophutha ngamaphutha afihliwe okunzima ukuthola. |

| Ukusebenza kahle | Ikhulisa izexwayiso zakuqala zokwehluleka kwemishini, ngcono ukusebenza kokukhiqiza okuphelele. |

| Inciphise amanani e-scrap | Kuqinisa ukusebenza kahle futhi kunciphise imfucuza inqubo yokwenza. |

| Ukwehliswa kwezindleko zokulungisa | Yehlisa imvamisa nezindleko zokulungiswa ngama-analytics wokuqagela. |

Izicelo ze-Pneumatic ezinikwe amandla

Ukuhlanganiswa kwe-IOT kukhulise izinhlelo zokusebenza zokufakwa kwe-pneumatic emikhakhelweni. Lokhu kufakwa okuhle manje kudlala indima ebalulekile ezinhlelweni zokulungiswa kwedatha. Ngokuhlinzeka ngemininingwane ye-sensor yesikhathi sangempela, banika amandla opharetha ukuhlela ukulungiswa ngempumelelo futhi baphendule ngokushesha izingqinamba. Le ndlela ayikhuliseli ukusebenza kwempahla kuphela kepha futhi iqinisekisa ukusebenza okungaphazamiseki. Izimboni ezinjengokukhiqiza kanye nokunakekelwa kwempilo zizuza kakhulu kulezi zinto ezithuthukayo, njengoba zincike ezinhlelweni ze-pneumatic eziqondile nezisebenzayo zokugcina amazinga aphezulu okusebenza.

Ukusebenza kahle kwamandla nokusimama

Izixazululo ze-pneumatic ezinobungane

Izisombululo ze-eco-friendly pneumatic ziguqula izimboni ngokunciphisa umthelela wezemvelo futhi zikhuthaza imikhuba esimeme. Ama-pneumatic system system designs anciphisa ukuvuza komoya, okunganciphisa amandla alahlekile ngo-10% kuya ku-20%. Lokhu kuthuthukiswa akugcini nje ngokulondolozwa amandla kepha futhi kusekela izinhloso zokusimama kwezinkampani. Ubuchwepheshe obuthuthukisiwe, obunjengokwenziwa ngcono kokubekwa uphawu kanye nezinto ezincishiswe ukungqubuzana, bukhulisa ukusebenza kahle kwamandla. Lokhu okusha kufaka isandla ekwehlisweni okukhulu ekuphumeni kwekhabhoni, kuvumelana nemizamo ye-Global Decarbonational. Ngokwamukela izixazululo ze-pneumatic eco-friendly, izimboni zingafinyelela ukwabiwa kwezinsiza ezingcono futhi zehlise izintambo zazo zemvelo.

Imiklamo Ekonga Amandla

Imiklamo yokonga amandla ku-pneumatic systems Gxila ekusebenzeni kahle ngenkathi inciphisa ukusetshenziswa kwamandla. Isibonelo, ukunciphisa ukunciphisa amazinga okucindezela kanye nokugcwalisa amavolumu wehlisa isidingo sokugeleza kwesisindo esingenhla, okuholela ekusebenzeni kahle. Ukufakwa kwama-pneumatic okusheshayo okuqokiwe, owaziwa ngokuqina kwawo kanye nekhono lokuvimbela ukuvuza komoya, adlale indima ebalulekile kule miklamo. Ngokwengeziwe, intuthuko yezobuchwepheshe kuma-compressors kanye nezihlungi zithuthukise ukusebenza kahle kwamandla ezingxenyeni ezahlukahlukene. Isibonelo, ama-compressos we-centrifugal afinyelela amanani asebenza kahle afinyelela ku-63.4%, kuyilapho ngemuva kokuphola kusebenza ngokusebenza kahle kwama-99%. Lokhu okusha kuqinisekisa ukuthi izinhlelo ze-pneumatic zihlala zibiza kakhulu futhi zinobungani bemvelo.

Izinzuzo Zokusebenza Zokusebenza Zokuqina

Ukusimama ezinhlelweni ze-Pneumatic kunikeza izinzuzo ezingezinhle zokusebenza kwezindleko. Ngokubhekana nokungasebenzi kahle, njengokuvuza komoya, izinkampani zinganciphisa ukulahleka kwamandla nge-20%. Lokhu kuhumushela ekunciphiseni izikweletu zamandla kanye nokubuyiselwa okuncane kwemishini. Imiklamo yohlelo olusebenzayo ibuye ithuthukise ukusebenza komshini, ukunciphisa izindleko zokuphumula nezindleko zokugcina. Ngaphezu kwalokho, imikhuba esimeme, njengokusebenzisa izinto eziqinile kanye nobuchwepheshe bokonga amandla, kubangele ukonga isikhathi eside. Izimboni ezibeka phambili ukuqina kokusikwa kungagcini nje ngokusika izindleko kodwa futhi zithuthukisa ukuncintisana kwazo kwemakethe ngokubonisa ukuzibophezela ekuqinisekeni kwemvelo.

I-miniaturization kanye nemiklamo ecwebezelayo

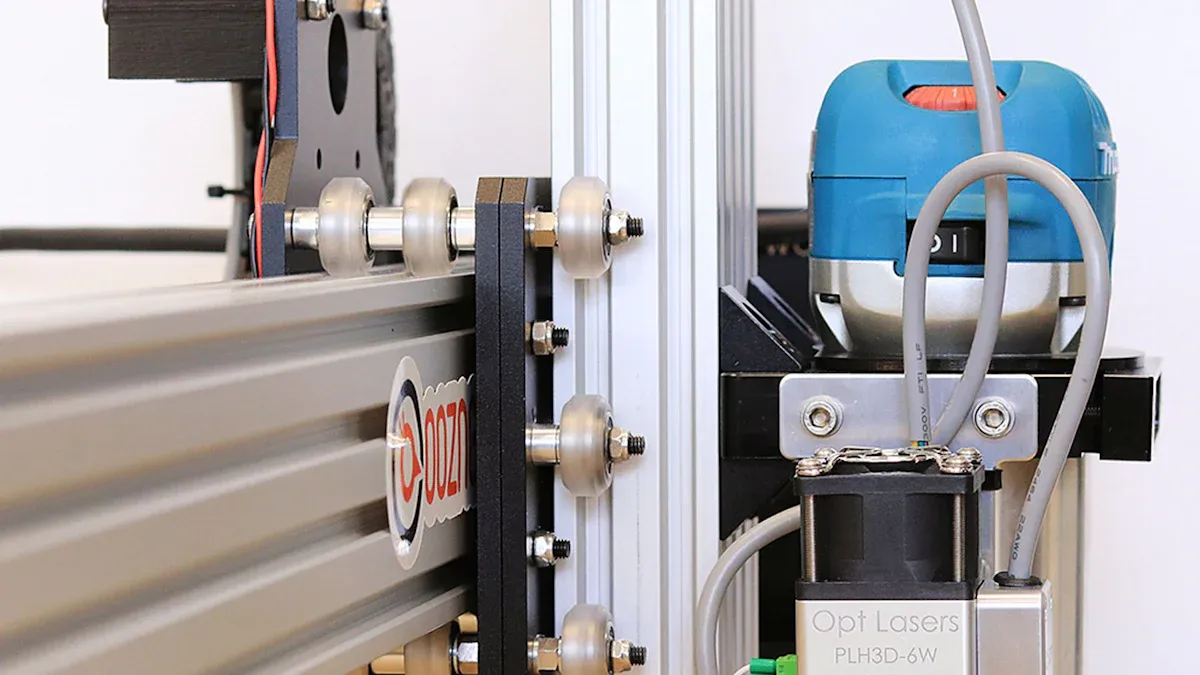

Funa ukufakwa kwama-pneumatic amancane

Isidingo sokufakwa kwezimali okuncane kwe-pneumatic siyaqhubeka nokukhula njengezimboni ezibeka phambili amasistimu acwebile futhi afanele. I-automation yezezimboni iye yaqhutshwa lo mkhuba, nabakhiqizi bafuna ukwakheka okungasindi kanye nokusindisa isikhala ukuze basebenzise imisebenzi. Le khasiUkufaneleka kwe-pneumaticImakethe ikhombisa lokhu kuguqulwa, njengoba izingxenye ezihlangene zinika amandla ukufakwa okuhleliwe futhi kunciphise isisindo sohlelo. Lezi zithuthuka zibhekela izimboni ezinjengamarobhothi nama-elekthronikhi, lapho izingqinamba ze-Space nokunemba zibaluleke kakhulu.

Izicelo zemiklamo ehlanganisiwe

Ukufakwa kwe-pneumatic compact thola izinhlelo zokusebenza emikhakheni ehlukahlukene edinga ukusebenza okuphezulu ezikhaleni ezilinganiselwe. Isibonelo, ngokwesibonelo, izinzuzo ezivela kule miklamo ngokuthola ukuguquguquka okukhulu nokunemba kokunyakaza. Ngokufanayo, amadivaysi ezokwelapha, anjenge-ventilator namathuluzi okuhlinza, ancike ekufakweni okuhlangene ukuze alondoloze ukusebenza ngaphandle kokuyekethisa ukubekezelela. I-Energy Savings iphinde ithuthukise isikhalazo sabo:

- Ukumisa ukuvuza komoya kunciphisa amandla alahlekile ngo-10% kuya ku-20%.

- Ukuhlanganisa ukuvimbela ukuvuza ngemiklamo ye-Smart kusiza ukulondolozwa kwamandla okufika kwaba ntathu.

- Izicelo ezibanzi zomoya, njengokuhlanza, zuza ukusebenza kahle okukhulu uma kuqhathaniswa nezinqubo zemishini.

Lezi zinzuzo zenza ama-compact design abaluleke kakhulu ezimbonini ezihlose ukuthuthukisa umkhiqizo kanye nokusimama.

IZINSELELE E-MINITIATULIZATION

Naphezu kwezinzuzo zayo, ukuzalanisa okuncane kuba nezinselelo. Ukufakwa okuncane okudinga amasu aqondile okukhiqiza, okungakhulisa izindleko zokukhiqiza. Ngokwengeziwe, ukulondolozwa kokuqina nokusebenza emiklamo ecwebile kudinga izinto ezithuthukile nobunjiniyela. Ukuqinisekisa ukuhambisana nezinhlelo ezikhona futhi kubangela ubunzima, njengoba izakhi ezincane zingadinga amathuluzi akhethekile noma adaptha. Ukunqoba lezi zinselelo kubalulekile ukuze uqaphele ngokuphelele amandla ezinhlelo ze-pneumatic ezincane.

Izinto ezithuthukisiwe namasu okukhiqiza

Izinto ezingasindi futhi eziqinile

Intuthuko ekwenzeni okungasindi futhi izinto ezihlala isikhathi eside zithuthukise kakhulu ukusebenza kanye nokwethenjwa kwezithako ze-pneumatic. Igqoko eliphakeme ukusebenza, njengama-polymers athuthukile, ukuvikela ekugqokeni nasekunciphiseni ngenkathi kunciphisa ukungezwani. Lezi zimbozo zithuthukisa isikhathi eside sokufakelwa, ukuzenza zilungele ukuthola izindawo ezifunwa kwezimboni. Ngokwengeziwe, imiklamo emisha, kufaka phakathi izindlela zokuxhuma nokuxhuma nokucushwa modular, anakekele izidingo ezingasindi futhi yenza lula izinqubo zokufaka.

| Uhlobo lwentuthuko | Ukufanisa |

|---|---|

| Ukumboza ukusebenza okuphezulu | Ama-polymers athuthukile ahlinzeka ngokuvikelwa ekugqokeni, ukugqwala, kanye nokuthuthukisa ukusebenza ngokunciphisa ukungezwani. |

| Imiklamo emisha | Izici ezinjengezindlela zokuxhumanisa nezingcingo kanye nemiklamo ejwayelekile Thuthukisa ukufakwa bese unakekela izidingo ezingasindi. |

Ukuhlanganiswa kwalezi zinto zokwenziwa kuqinisekisa ukuthi ukufakwa kwe-pneumatic kuhlala kuqine futhi kusebenza kahle, ngisho nasekuhlolweni okuphezulu noma okushisa okuphezulu.

Ukuphrinta kwe-3D kuma-pneumatic Fittings

Ukuphrinta kwe-3D kuguqule ukukhiqizwa kokufakwa kwe-pneumatic ngokunika amandla ama-prototyping kanye nokwenza ngokwezifiso. Lobu buchwepheshe buvumela abakhiqizi ukuthi bakha ama-geometries ayinkimbinkimbi ayekade angenakwenzeka ngezindlela zendabuko. Isibonelo, ukufakwa okuphrintiwe kwe-3D kungafaka iziteshi zangaphakathi ze-airflow eyenziwe kahle, ukuthuthukisa ukusebenza kahle kohlelo. Ukusetshenziswa kwezinto ezingasindi, njengama-polymers athuthukile, kunciphisa futhi isisindo sezakhi ngaphandle kokuyekethisa ukuqina. Izimboni ezinjenge-aerospace kanye nenzuzo yezimoto kusuka kulolu hlelo lokusebenza olusha, njengoba lusekela ukuthuthukiswa kwezinhlelo ezihlangene kanye nokusebenza kahle.

Izinzuzo eziqondene nezinto ezibonakalayo ezikhethekile

Izinto ezithuthukisiwe ekufani kwe-pneumatic anikela ngezinzuzo ezihambisanayo kuyo yonke imboni ehlukahlukene. Kwi-automation namarobhothi, izinto ezingavikezi ezingasindi futhi ezingamelana nokugqwala zithuthukisa ukusebenza kahle kanye nokwethembeka. Izindlela zokuxhuma nokuxhuma kanye nokuxhuma okusheshayo kokuxhumanisa ukunciphisa isikhathi sokuphumula, ukukhiqiza okwandayo ezindaweni zokukhiqiza. Ubuchwepheshe obunobuhlakani obuhlanganiswe ekufakweni nikwazi ukubhekwa kwangempela kwamapharamitha sohlelo, ukulungiselela ukusebenza kanye nokwehlisa izindleko zokusebenza. Lezi zici zenza ukufakwa kwe-pneumatic okubaluleke kakhulu kwizimboni ezidinga ukunemba nokusebenza kahle.

- Ama-design ajwayelekile anakekela izixazululo ezihlanganisiwe nezingasindi, ezibalulekile ze-aerospace kanye nezicelo zezimoto.

- Izici ezinjenge-QuSCH-Disconctact Couplings zithuthukisa ukusetshenziswa futhi zinciphise isikhathi sokulungisa.

- Amandla okuqapha wesikhathi sangempela athuthukisa ukuthembeka kohlelo futhi anciphise isikhathi sokuphumula.

Ngokufaka izinto ezithuthukisiwe, izimboni zingathola umkhiqizo ophakeme kanye nokusimama, ukuqinisekisa impumelelo yesikhathi eside.

Ukwenza ngokwezifiso nezixazululo eziqondene nohlelo lokusebenza

Ukufakwa kwe-pneumatic

Ukufakwa kwe-pneumatic okuhlanganisiwe kubhekana nezidingo ezihlukile zezimboni ezahlukahlukene ngokunikeza izixazululo ezenziwe ngezifiso. Lokhu kufakwa ezivumelana nezidingo ezithile zokusebenza, ukuqinisekisa ukusebenza kahle kanye nokuhambisana. Isibonelo, izimboni ezinezinhlelo eziphakeme zengcindezi zizuza kusuka kuma-Fittings aklanyelwe ukubekezelela izimo ezedlulele, ngenkathi imikhakha edinga ukunemba, njengokunakekelwa kwempilo, okuthembela ekufundeni ngokunemba okuthuthukisiwe. Ukwenza ngokwezifiso kubuye kufinyelele ekukhetheni kwezinto ezibonakalayo, lapho izinketho ezingasindi futhi zingamelana nokugqwala zithuthukisa ukuqina nokusebenza kahle. Ngokuhambisa ama-pneumatic fittings, abakhiqizi bangahlangabezana nezidingo eziqondile zezicelo zabo, ukuthuthukisa ukuthembeka nokwehlisa isikhathi sokuphumula.

Izibonelo ezenziwe ngezifiso eziqondene nokwezifiso

Ukwenza ngokwezifiso kudlala indima ebaluleke kakhulu kwizimboni ezifana ne-automation, amarobhothi kanye ne-aerospace. Kwi-automation, ukufakwa kwe-pneumatic ukuxhumeka kokuxhumeka okuphephile nokuvuzayo, okubalulekile ukuze kugcinwe ukuthembeka kohlelo. Izicelo zeRobotic zivame ukudinga ukufakwa okusiza ukulawulwa okuqondile kwengcindezi yomoya nokugeleza, okunika amandla ukunyakaza okunembile nangokufanele. Izimboni ze-Aerospace Industry zizuza ezifweni ezingasindi futhi ezihlanganisiwe ezinciphisa isisindo sohlelo lonke ngaphandle kokuyekethisa ukusebenza. Lezi zibonelo ziqokomisa ukuthi ukwenza ngezifiso kuthuthukisa kanjani ukusebenza kanye nokukhiqiza kwezinhlelo ze-pneumatic emikhakheni ehlukahlukene.

Ukuthuthuka Kokusebenza Kahle Ngokwezifiso

Ukufakwa kwe-pneumatic okwenziwe ngokwezifiso kuthuthukisa ukusebenza kahle kokusebenza. Ngokuqinisekisa ukulawulwa okuqondile kwengcindezi yomoya nokugeleza, lokhu kufakwa kuthuthukisa ukusebenza kwezinhlelo ezenzakalelayo. Lokhu kunembe kunciphisa imfucuza yamandla futhi kuthuthukisa imishini yokukhiqiza imishini. Imiklamo ehlanganisiwe ibuye inciphise ukuvuza komoya, okuholela ekunciphiseni izindleko zamandla ezifika kuma-30%. Ithebula elingezansi lifingqa lokhu kuthuthukiswa:

| Isici Sokwenza ngcono | Idatha Yezinombolo |

|---|---|

| Ukuncishiswa kwezindleko zamandla | Kufika kuma-30% |

Ukwenza ngokwezifiso akugcini nje ngokusebenzisa ukusetshenziswa kwamandla kepha futhi kunwebe isikhathi sokuphila kwemishini, ukunciphisa izindleko zokulungisa kanye nokuqinisekisa ukuqina kwesikhathi eside.

Ukuhlanganiswa kwe-automation kanye namarobhothi

Ukufakwa kwe-pneumatic ezinhlelweni ezenzakalelayo

Ukufakwa kwe-pneumatic kudlala indima ebalulekile ezinhlelweni ezenzakalelayo ngokuqinisekisa ukuxhumana okuphephile nokusebenza kahle phakathi kwezakhi. Lokhu kufakwa kunika amandla ukuphathwa okuqondile kwengcindezi yomoya nokugeleza, okubalulekile ekusebenzeni okubushelelezi kwemishini. Izici ezinjengezindlela zokucindezela ukuxhuma kanye nokuxhumeka okusheshayo okusheshayo kwenze lula izinqubo zomhlangano futhi zinciphise isikhathi sokuphumula. Ubuchwepheshe obunobuhlakani obuhlanganiswe nokufakwa kwe-pneumatic bukhulisa ukusebenza kwabo ngokunika amandla ukuqapha kwangempela kwamapharamitha wesistimu. Lokhu kubona kuthuthukisa ukusebenza kahle, kunciphisa izindleko zokusebenza, futhi kuqinisekisa ukusebenza okungaguquki ezindaweni ezenzakalelayo.

Izicelo zeRobotic

Amarobhothi athembele kakhulu ekufakweni kwe-pneumatic ukufezekisa ukunemba nokwethenjwa. Lokhu kufakwa lula ukunyakaza okulawulwa kwezingalo ze-robotic nezinye izinto ngokulawula ingcindezi yomoya nokugeleza. Imiklamo ethambile futhi engasindi ye-compact inenzuzo ikakhulukazi kumarobhothi, lapho izingqinamba ze-Space nokuqina kubalulekile. Isibonelo, ukufakwa kwe-pneumatic kuma-robotic gripper kuqinisekisa ukuphathwa okunembile kwezinto ezibuthakathaka, kubenza babaluleke kakhulu ezimbonini ezinjenge-elekthronikhi kanye nokunakekelwa kwempilo. Amandla okugcina ukusebenza okungaguquki ngaphansi kwezimo ezahlukene aqokomisa ukubaluleka kwawo ekuthuthukiseni ubuchwepheshe be-robotic.

Izinzuzo Zokuhlanganisa ze-automation

Ukuhlanganiswa kokufakwa kwe-pneumatic ezinsizeni ezenzakalelayo kunikeza izinzuzo eziningi. Lezi zinhlaka zithuthukisa ukuthembeka kohlelo ngokuvimbela ukuvuza komoya kanye nokuqinisekisa amazinga okucindezela angaguquki. Izinqubo Zomhlangano Osheshayo, ezinikwe amandla ngemiklamo efanelekile efanelekile, zinciphise isikhathi sokukhiqiza futhi zikhuphule ukusebenza kahle. Amakhono okuqapha wesikhathi sangempela avumela abahlinzeki ukuthi bakhombe futhi babhekane nezinkinga ngokushesha, ukunciphisa izindleko zokuphumula kanye nezindleko zokugcina. Ngokwenza ngcono ukusebenza kahle kokusebenza kanye nokunciphisa ukusetshenziswa kwamandla, ukufakwa kwe-pneumatic kufaka isandla ekusimeni kanye nokusebenza kwezindleko zezinhlelo ezenzakalelayo.

Izindinganiso Zokuphepha Nokuhambisana

Ukunamathela kwimigomo Yezimboni

Ukuhambisana nemithetho yezimboni kubalulekile ekuqinisekiseni ukuphepha kanye nokwethenjwa kwezinhlelo ze-pneumatic. Izindinganiso Zokulawula zilawula ukwakheka, ukukhiqiza, kanye nokusetshenziswa kwama-pneumatic Fittings ukuvikela ukwehluleka okusebenzayo kanye nezingozi. Izimboni zanda zithembela ezenzakalelayo, lapho ukufakwa kwe-pneumatic kudlala indima ebalulekile ekuxhumaniseni izinto nokugcina ukusebenza kahle kohlelo. Ukulandela le mithethonqubo kuqinisekisa ukuthi izinhlelo ezenzakalelayo zisebenza ngempumelelo ngenkathi zinciphisa ubungozi.

Izici ezibalulekile Ukulandela Ukulandela Ukulandela:

- Isidingo esikhulayo se-automation ezigatsheni ezahlukahlukene.

- Isidingo sokuqinisekisa ukuphepha nokusebenza kahle emishini ezenzakalelayo.

- Indima ebalulekile yokufakwa kwe-pneumatic ekugcineni ukusebenza okusebenzayo.

Ngokulandela lezi zindinganiso, abakhiqizi bangahambisa imikhiqizo ehlangabezana namabhentshi okuphepha futhi uthole ukwethenjwa kwamakhasimende.

Ukufakwa kwe-pneumatic okugxile ekuphepheni

Ukufakwa kwe-pneumatic okugxile ezokuphepha kwenzelwe ukubekezelela izimo ezimbi kakhulu futhi kuvikele ukwehluleka kohlelo. Izici ezinjengezimpawu zophawu oluvuzayo, izinto zokulwa nokugqwala, kanye nemiklamo yokuvimbela ingcindezi ithuthukisa ukuthembeka kwabo. Lokhu kufakwa kunciphisa ubungozi bezingozi ezibangelwa ukuvuza komoya noma ukuguquguquka kwengcindezi, ukuqinisekisa ukusebenza okuphephile ezindaweni ezifunwayo. Isibonelo, izimboni ezinjengokunakekelwa kwempilo kanye ne-aerospace zizuzwa kusuka ekuqondeni okugcina ukusebenza okungaguquki ngaphansi kwengcindezi ephezulu noma ukuhlukahluka kwezinga lokushisa. Imiklamo egxile ekuvikelweni ayivikeli imishini kuphela kodwa futhi ivikele abasebenzi abasebenza nezinhlelo ze-pneumatic.

Ukuthobela kanye nokuthembela kwemakethe

Ukuhambisana nezindinganiso zokuphepha kanye nezinga lekhwalithi kwakha ukwethenjwa emakethe. Amakhasimende abeka phambili imikhiqizo ehlangabezana nezidingo zokulawula, ngoba lokhu kuqinisekisa ukuthembeka nokuphila isikhathi eside. Abakhiqizi abanamathela ezindinganisweni zokuhambisana nokuthola umphetho wokuncintisana ngokukhombisa ukuzibophezela kwabo ekuphepheni nasezingeni. Ngaphezu kwalokho, ukuthobela kunciphisa amathuba ezindabeni zomthetho nokuphazamiseka okusebenzayo, okwenza ngcono idumela lenkampani. Ukufakwa kwe-pneumatic okuhlangabezana nalezi zindinganiso kufaka isandla ekuthembekeni okuphelele kwezinhlelo ezenzakalelayo, okwenza babaluleke kakhulu kwizimboni zanamuhla.

Imboni efanelekile ye-pneumatic ivela ngokushesha, iqhutshwa yizitayela njengokuhlanganiswa kwe-IOT, amandla amandla okusebenza, kanye ne-miniaturiation. Izinto ezintsha ezintweni zokwakha kanye namasu okukhiqiza aqinisekisa ukuqina nokuvumelana nezimo emikhakheni yonke. Ithebula elingezansi liqokomisa amathrekhi asemqoka abumba imakethe ngo-2025:

| Umkhuba | Ukufanisa |

|---|---|

| Ukwemukelwa kwe-Smart pneumatic systems | Ukuhlanganiswa kwezinzwa nobuchwepheshe be-IOT bokuqapha real-time kanye nokulondolozwa kokubikezela, ukuthuthukisa ukusebenza kahle kohlelo. |

| Ukugxila okwandayo ekusebenzeni kwamandla | Isidingo sokufakelwa okunciphisa ukuvuza komoya futhi kunciphise ukusetshenziswa kwamandla, okuqhutshwa ngokusimama kanye nokonga izindleko. |

| Ukukhula kokwenza ngokwezifiso kanye nokufakwa kohlelo lokusebenza | Abakhiqizi bahlinzeka ngobubanzi obubanzi bokufakelwa okwenziwe ngezifiso ukufeza izidingo ezithile zomkhakha, ezisekelwa yintuthuko njengokuphrinta kwe-3D. |

| Ukwemukelwa kwezinto ezithuthukisiwe | Okuthandwayo ama-composites athuthukile nama-polymers wesisindo esincishisiwe nokuqina okuthuthukile, okuvumela ukufakwa ekubekezeleleni izimo ezimbi kakhulu. |

| I-miniaturization yezakhi ze-pneumatic | Isidingo sokufakelwa okuncane, okusebenzayo kumadivayisi acwebile, ikakhulukazi kuma-elekthronikhi kanye nemikhakha yezokwelapha. |

| Ukunwetshwa kwesiteshi sokusatshalaliswa kwe-e-commerce | Ukukhula kwamapulatifomu akwi-inthanethi ukufinyelela okulula kokufakwa kwe-pneumatic, ukuthuthukisa ukusebenza kahle kokuthengwa kokuhlinzekwa. |

| Izindinganiso Zokuphepha Nezintambo Zokuncintisana | Ukwanda kwezidingo zokulawula ukushayela ezintsha ekwakhiweni nezinto zokwakha ukuze kuhlangatshezwane nezindinganiso zezokuphepha eziphakeme nezemvelo. |

Ukusungula kugcina kubalulekile ukuze kugcinwe ukuncintisana kule ndawo enamandla. Izimboni kumele zamukele lezi zithuthuka ukwandisa imisebenzi futhi zifinyelele izinhloso zokusimama. Ukuhlala unolwazi mayelana nobuchwepheshe obuqhamukayo kuqinisekisa amabhizinisi asasele kule nkathi eguqukayo.

Umthandi

Yiziphi izimboni ezizuzisa kakhulu ekufakineni kwe-pneumatic?

Ukufakwa kwe-pneumatickubalulekile ekwenziweni, ekunakekelweni kwezempilo, i-aerospace, namarobhothi. Lezi zimboni zithembela ekuphathweni komoya okuqondile ukuze zisebenze kahle futhi zithembekile.

Ukuhlanganiswa kwe-Iot kuthuthukisa kanjani izinhlelo ze-pneumatic?

Ukuhlanganiswa kwe-IOT kwenza ukuqapha isikhathi sangempela kanye nokunakekelwa kokubikezela. Lokhu kunciphisa isikhathi sokuphumula, kuthuthukisa ukusebenza kahle, futhi kuqinisekise ukusebenza kahle kohlelo.

Uthiphu: Ukutshala imali ezinhlelweni ze-pneumatic enikwe amandla ama-Iot kunganciphisa kakhulu izindleko zokusebenza ngokuhamba kwesikhathi.

Ingabe ukufakwa kwe-pneumatic compact kuhlala isikhathi eside njengakwejwayelekile?

Yebo, ukufakwa okuhlangene kusetshenziswa izinto ezithuthukisiwe nobunjiniyela ukuze kugcinwe ukuqina. Benza ngokuthembekile ngisho nasezindaweni ezicindezelwe noma ezicindezelwe kakhulu.

Isikhathi sePosi: Mar-29-2025