Ingcindezi yoMfutho we-Hydraulic Valve Pilot isebenze i-varve cartrify cartridge valve xyf10-08

Bonisana

Izinto ezibonakalayo:Imishini eqondile yomzimba we-valve

Imvelo Yengcindezelo:ingcindezi ejwayelekile

Indawo yokushisa imvelo:okukodwa

Izesekeli Ongakukhetha:umzimba we-valve

Uhlobo lweDrayivu:iqhutshwa amandla

Okusebenzayo okusebenzayo:Imikhiqizo kaPetroleum

Amaphuzu okunakwa

Izinzuzo ze-Hydraulic Systery Cartridry Valves

Ngoba i-cartridge logic valve ihlelwe ekhaya nakwamanye amazwe, noma ngabe yi-International Standard Iso, i-German Din 24342 nezwe lethu (i-GB 2877 standard) i-Hardve Valve, okubuye kufakazelwe ukwakheka kwe-Hydraulic valve kukhiqize igumbi elibanzi.

I-cartridge Logic Valve kulula ukuyihlanganisa: Izakhi eziningi zingagxila emzimbeni we-block ukwakha uhlelo lokulawula lwe-hydraulic, olunganciphisa isisindo sengcindezi ehlanganiswe ngokucindezela okujwayelekile, ukuqondiswa kanye no-1/4, futhi ukusebenza kahle kunganyuswa ngo-4% kuye ku-4%.

Ijubane lokuphendula okusheshayo: ngoba i-carcher valve isakhiwo se-valve yesihlalo, i-spool iqala ukudlula kawoyela ngokushesha nje lapho ishiya isihlalo. Ngokuphambene nalokho, isakhiwo se-slide valve kufanele siqede inani lesembozo ngaphambi kokuqala ukuxhuma umjikelezo kawoyela, nesikhathi sokuqedela impungaleko yegumbi lokulawula bese uvula i-carcher valve cishe kuphela, futhi ijubane lokuphendula lishesha.

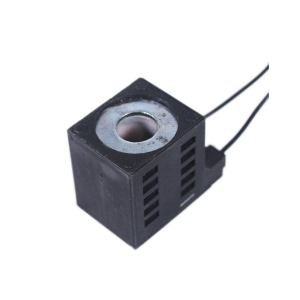

Isimiso se-Volenoid Valve eqondile: Lapho amandla, amandla e-electromagnetic akhiqizwe yi-electromagnetic Coil ephakamisa ingxenye yokuvala esihlalweni, futhi i-valve ivula; Lapho amandla evaliwe, amandla e-electromagnetic ayanyamalala, intwasahlobo icindezela ingxenye yokuvala esihlalweni, futhi i-valve ivaliwe.

Isinyathelo ngesinyathelo Direct Direct Acting Soling Solenoid Valve Religiple: Isimiso Sokushayela Ngokuqondile Nesivumelwano Sokushayela, uma kungekho mehluko wokucindezela phakathi kwe-inlet kanye nokuphuma, ngemuva kwamandla, i-valve evala izingxenye ngqo, i-valve iyavuleka. Lapho i-inlet kanye nokuphuma kufinyelela umehluko wokuqala wengcindezelo, ngemuva kwamandla, i-electromagnetic Force Pilot TRESS GEEST, ukucindezela kwengcindezi ephezulu, ukuze usebenzise umehluko wengcindezi wokucindezela i-valve enkulu kuya phezulu; Lapho amandla evaliwe, i-Pilot Valve isebenzisa amandla entwasahlobo noma ingcindezi ephakathi ukucindezela ingxenye yokuvala futhi iqhubekele phansi ukuze ivale i-valve.

Umgomo we-Pilot Solenoid Valve: Lapho amandla aphethwe amandla, amandla e-electromagnetic avula umgodi wokushayela, ingcindezi ephezulu yeChamber yehle ngokushesha, ekwakheni umehluko wengcindezi ephansi futhi ephezulu ezungeza ingxenye yokuvala, i-valve ivuleka; Lapho amandla esephelile, amandla entwasahlobo avala umgodi wokushayela, futhi ingcindezi yokungena enomehluko wokuphumula okuphezulu ezungeze umgodi we-valve ngokushesha, futhi ingcindezi kamanzi icindezela ukuvalwa phansi nokuvala i-valve.

Ukucaciswa komkhiqizo

Imininingwane yenkampani

Inzuzo Yenkampani

Ukuthutha

Umthandi