Isikhundla Esinezindlela Ezimbili Ngendlela Engabuyiswa Nge-Hydraulic Valve Sv10-44

Bonisana

Isenzo esisebenzayo:Uhlobo Lokubuyisela emuva

Impahla yokulinganisa:insimbi ye-alloy

Ukubopha uphawu:okokuhlikihla

Indawo yokushisa:Ukushisa okujwayelekile komkhathi

Ukugeleza kokugeleza:uMhamfri

Izesekeli Ongakukhetha:ikhohla

Izimboni ezisebenzayo:izinsimbi zomshini

Uhlobo lweDrayivu:Electromagnetism

Okusebenzayo okusebenzayo:Imikhiqizo kaPetroleum

Isingeniso Somkhiqizo

Kuhlelo lwensimu, ama-valves amaningi we-electromagnetic thrined cartradge ajwayele ukubangelwa yikhwalithi yokulawula i-valve uqobo, kepha ngamaphutha wokufaka adalwa yimvelo, isikhundla esingenangqondo sokufaka kanye namapayipi angachazwanga. Ngakho-ke, ukunakwa kufanele kukhokhwe kulezi zinto ezilandelayo lapho ufaka futhi usebenzisa i-valve kagesi yokulawula:

. (1 Uma ifakiwe ngaphandle noma endaweni enamazinga okushisa aphezulu aqhubekayo, ifektri esebenza ngokuqondile, i-aclowflew flow valve factory kufanele isebenzise izinyathelo zokufaka amazinga okushisa. Ezindaweni ezinemithombo yokuzamazama komhlaba, kuyadingeka ukugwema imithombo yokudlidliza noma ukuthuthukisa izindlela zokuvimbela ukuzamazama komhlaba.

.

(3) Ngaphansi kwezimo ezijwayelekile, ipayipi lokufaka i-valve elawula ngeke libe liphezulu kakhulu ukusuka endaweni yomgwaqo noma esitezi sokhuni. Lapho ukuphakama okuhlobene kwepayipi kudlula i-2m, ipulatifomu yensizakalo kufanele isethwe ngangokunokwenzeka ukwenza lula isondo nokulungiswa kwe-opharetha.

(4) Ngaphambi kokufakwa kwe-valve yokulawula, ipayipi lizohlanzwa ukuze lisuse ukungcola kanye nesibazi se-welding.

Ngemuva kokufaka i-Pilot Surve valve, ukuze kuqinisekiswe ukuthi izinsalela azihlali emzimbeni we-valve, umzimba we-valve kufanele uhlanzwe futhi, okungukuthi, wonke ama-vasters ama-valves kufanele angeniswe lapho kuvimbela izinsalela ukuba zibambelele. Ngemuva kokuthi isakhiwo se-spindle sisetshenzisiwe, kufanele sibuyiselwe endaweni yokungathathi hlangothi kwangaphambili.

.

Ngasikhathi sinye, kufanele sinake futhi ukuthi ingxenye yokufaka ye-control valve ihlangabezana nezidingo zenqubo yonke yokucubungula.

(6) Ngokwezidingo zokwakha ezihlobene nemishini kagesi, ezinye izinto zikagesi ze-Electric Control Valve zizofakwa. Uma kwenzeka izimpahla zobufakazi bobufakazi, kufanele zifakwe ngokuya ngekhodi yokufakwa kwemishini kagesi ezindaweni eziqhuma eziyingozi. Uhlobo lwe-sbh noma uhlobo lwayo .3 sbh noma amanye ama-cores ayisithupha noma ayisishiyagalombili.

Ukulungiswa kwesicelo, kwenqatshelwe ukuxhuma nokuvula ikhava yemitha yokulungiswa kanye ne-PRY i-FlameProof ebusweni ezindaweni ezivuthayo neziqhumayo. Ngasikhathi sinye, akudingekile ukuqubuka noma ukuklwebheka i-flameproof engaphezulu ngesikhathi sokuhlukaniswa, futhi imithetho yase-FlameProof yokuqala kufanele ibuyiselwe ngemuva kokulungiswa.

(7) Ngemuva kokuthi ukuncipha kuhlakazekile, kufanele kubhekwe ekuhlolweni kwamafutha, futhi ama-motors anesivinini esiphansi ngokuvamile awadingi ukuhlukaniswa ngamafutha. Ngemuva kokufaka, hlola ukuthi isikhundla se-valve sihlangabezana yini nesibonakaliso sokuvula isikhundla se-valve.

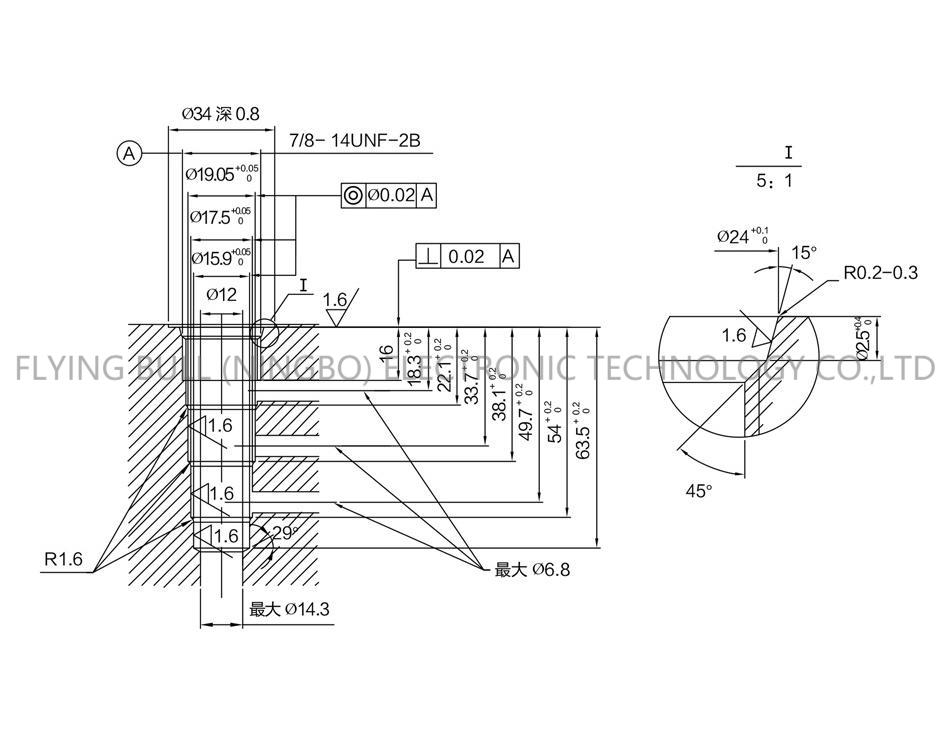

Ukucaciswa komkhiqizo

Imininingwane yenkampani

Inzuzo Yenkampani

Ukuthutha

Umthandi